Table of Contents

This shipping container buying guide is a comprehensive resource that will help you navigate the process of purchasing the right storage container for your specific needs, budget, and timeline. Whether you’re a first-time buyer looking for secure storage, a business owner planning expansion, or a homeowner considering a unique building project, this guide will eliminate the guesswork and prevent costly mistakes.

Quick Glossary of Container Conditions

The container industry uses specific terminology to describe condition grades. Understanding these terms prevents miscommunication and ensures you get exactly what you expect.

One-Trip (Like New)

Definition: Containers manufactured specifically for sale, having made only one voyage from factory to destination port.

Condition: Factory-new condition with minimal wear

Best for: Premium applications, customer-facing locations, maximum lifespan requirements

IICL Storage Containers

Best for: Buyers wanting near-new quality at used container pricing

Definition: Premium used shipping containers, typically 10 years old or newer, that meet strict Institute of International Container Lessors standards

Condition: Minimal wear despite being used, very minimal rust kept to industry minimum standards, excellent structural integrity

Cargo-Worthy (CW)

Definition: Used containers certified safe for international shipping cargo

Condition: Structurally sound with minor cosmetic wear, fully weather-tight

Best for: Storage applications prioritizing value and functionality

Wind & Watertight (WWT)

Definition: Containers that prevent wind and water entry but aren’t certified for cargo shipping

Condition: May have cosmetic damage, possible minor repairs, but remain secure and dry

Best for: Budget storage where perfect condition isn’t required

Read our full guide on Understanding Shipping Container Grades/Conditions.

First, Understand the Fundamentals of Container Sizes & Types

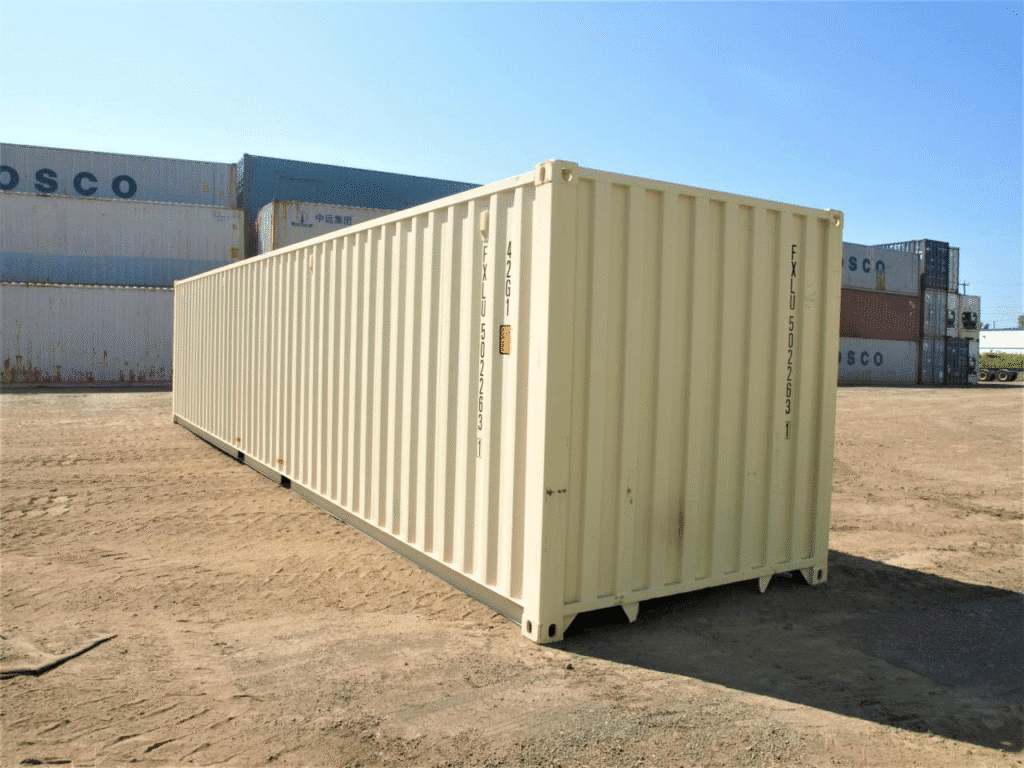

Before diving into prices or sellers, you need to understand what’s available in the shipping container buying market. Storage containers (also called cargo containers or CONEX in military/government applications) aren’t one-size-fits-all, each size and type serves different purposes, and choosing the wrong one is the most expensive mistake you can make in your container purchase.

Standard Shipping Container Dimensions

The shipping container industry revolves around two primary sizes that handle 90% of all applications. Understanding these standard dimensions will help you determine which option best fits your space and storage requirements.

The 20ft Standard Container

The 20-foot container measures 20′ long × 8′ wide × 8’6″ high externally, providing approximately 160 square feet of floor space. This compact powerhouse offers:

- 1,172 cubic feet of storage capacity

- Maximum payload: 62,350 lbs when fully loaded

- Perfect for: Home storage, small retail operations, job site storage, tiny home conversions

- Delivery advantage: Fits in tighter spaces and requires less ground preparation

Most residential customers choose 20-foot containers because they’re easier to place, require smaller delivery trucks, and cost significantly less than larger options while still providing substantial storage capacity.

The 40ft & High Cube (HC) Container

The 40-foot container comes in two height variations:

40ft Standard Container: 40′ × 8′ × 8’6″ (320 sq ft, 2,350 cubic feet)

40ft High Cube Container: 40′ × 8′ × 9’6″ (320 sq ft, 2,700 cubic feet)

The extra foot of height in High Cube containers makes a significant difference for:

- Commercial storage requiring vertical space for shelving

- Workshop conversions where headroom matters

- Agricultural use for equipment storage

- Retail applications with tall inventory

Expert Tip: High Cube containers cost only 10-15% more than standard height but provide 15% more storage volume. If your budget allows, they’re almost always the better choice for 40-foot purchases.

Other Sizes Offered

While 20-foot and 40-foot containers dominate the market, specialized sizes solve unique space and access challenges that standard containers can’t address.

10ft Container’s

At 10′ × 8′ × 8’6″, these containers offer 80 square feet and 586 cubic feet of secure storage. They’re ideal for:

- Urban locations with space constraints

- Construction sites requiring tool security

- Backyard workshops in HOA-restricted areas

- Seasonal storage that needs to be easily relocated

45ft Container’s

The 45-foot container (45′ × 8′ × 9’6″) provides 360 square feet and 3,040 cubic feet, crucial extra space for:

- Equipment storage requiring specific length clearances

- Retail operations needing extended display space

- Agricultural storage for long implements

- Manufacturing processes requiring linear workflow

Specialized Containers for Unique Needs

Standard containers have doors on one end only. Specialized access containers eliminate the frustration of reaching items stored in the back, making them essential for active storage and commercial applications.

Take a look at all the types of shipping containers E&S has to offer!

Double Door Containers (20′ & 40′): Access Your Goods from Both Ends

Double door containers feature full-size, lockable doors on both ends, effectively creating two separate storage zones or allowing drive-through access. Benefits include:

- Workflow efficiency: Load from one end, retrieve from the other

- Organization: Separate seasonal items, tools, or inventory types

- Vehicle storage: Drive equipment or vehicles completely through

- Improved ventilation: Cross-breeze when both doors are open

Open Side Containers (20′ & 40′): Unrestricted Access for Bulky Items

Open side containers feature full-length doors along one 20-foot or 40-foot side, creating an opening equivalent to removing an entire wall. This design excels for:

- Loading oversized equipment that won’t fit through standard doors

- Retail displays requiring wide customer access

- Workshop applications needing maximum opening flexibility

- Event storage where quick setup/breakdown matters

Quad-Door Containers:

Combining double doors with open side access, quad-door containers provide openings on three sides (both ends plus one side). While premium-priced, they’re unmatched for applications requiring maximum accessibility and workflow efficiency.

New vs. Used, Which Storage Container Is Right for You?

The new versus used shipping containers decision significantly impacts your budget, timeline, and long-term satisfaction. Each option serves different priorities, and understanding the trade-offs prevents buyer’s remorse.

New “One-Trip” Containers

New shipping containers, technically called “1-trip shipping containers” or “new” storage containers, have made only a single journey from the manufacturer to a US port. They represent the premium option in the container market, and come with 3 big pros.

- Pristine Condition & Maximum Lifespan

One-trip containers arrive with:

- Factory-fresh paint with no rust, dents, or wear marks

- Pristine wooden floors with no stains, damage, or odors

- Perfect door operation with tight seals and smooth mechanisms

- 25-30 year lifespan under normal conditions

- Aesthetically Pleasing for Customer-Facing Locations

New containers work best when appearance matters:

- Retail locations where customers see the container

- Residential areas with homeowner association requirements

- Commercial properties maintaining professional image

- Marketing or branding applications requiring custom paint

3) Peace of Mind with Near-Perfect Structural Integrity

With new containers, you eliminate concerns about:

- Hidden structural damage from previous cargo loads

- Contamination from unknown previous contents

- Premature maintenance needs or unexpected repairs

- Insurance or liability issues from container condition

Learn everything about 1-trip shipping containers

The Value of Used “Cargo-Worthy” Containers

Cargo-worthy shipping containers and used storage containers have been inspected and certified safe for international shipping. These cargo worthy containers offer exceptional value while maintaining structural integrity and weather resistance.

Significant Cost Savings for a High-Quality Product

Used shipping containers in cargo-worthy condition typically cost 30-50% less than new storage containers while providing:

- Certified structural integrity for heavy loads

- Proven weather resistance through ocean voyages

- 15-20 year remaining useful life

- Immediate availability from larger inventory pools

Proven Durability That Has Traveled the Globe

These containers have demonstrated real-world performance:

- Ocean-tested weather sealing under extreme conditions

- Load-proven structural strength from commercial cargo use

- Verified durability through rigorous shipping industry standards

The Ideal Solution for Secure, No-Frills Storage

Cargo-worthy containers excel when function trumps form:

- Industrial storage where appearance doesn’t matter

- Agricultural applications prioritizing protection over aesthetics

- Job site storage requiring security and weather resistance

- Budget-conscious projects needing maximum value

Want to know more? Read our full break down on new vs used shipping containers.

Timeline Expectations & Delivery Variables

Understanding realistic delivery timeframes helps you plan your project and avoid disappointment. Multiple factors affect when your container arrives, from inventory availability to weather conditions.

Standard Delivery Timeframes

Typical delivery timelines vary based on container type and modifications:

Standard Container Delivery:

- In-stock containers: 7-12 days from order confirmation

- Custom-sourced containers: 7-12 days depending on availability

- Standard modifications: 3-4 weeks for door additions, paint, etc.

Factors Affecting Timeline:

- Seasonal demand: Peak seasons (hurricane preparation, construction busy periods, agricultural harvest times) can extend delivery timelines as demand for containers increases significantly

- Inventory availability: In-stock vs special order containers

- Modification complexity: Simple vs extensive customization

Note: Seasonal demand is the primary factor affecting delivery schedules. During peak seasons, even in-stock containers may experience longer delivery times due to increased customer demand and delivery scheduling constraints.

Expedited Options for Urgent Needs

When you need a container quickly, expedited service can reduce standard timeframes:

Rush Delivery Available:

- 3-5 day delivery: Available for in-stock, unmodified containers

- Premium pricing: Expedited service typically incurs a slightly higher delivery fee.

- Geographic restrictions: May not be available in all delivery areas

Factors That Can Delay Your Delivery

Several common issues can extend delivery timelines beyond standard estimates:

Weather-Related Delays:

- Winter conditions: Snow, ice, or frozen ground preventing delivery truck access

- Heavy rain: Soft ground conditions that can’t support delivery equipment

- Extreme weather: High winds or storms that make delivery unsafe

Logistics and Access Issues:

- Site preparation delays: Inadequate ground preparation requiring additional work

- Access restrictions: Low overhead clearance or narrow access routes discovered late

- Permit delays: Last-minute permit requirements that weren’t anticipated

- HOA approval: Community approval processes taking longer than expected

Order and Inventory Factors:

- Specification changes: Customer modifications to original order

- Quality issues: Replacing containers that don’t meet standards

- Modification complexity: Custom work taking longer than estimated

- Inspection requirements: Additional quality control for specialized applications

Understanding Total Delivered Pricing

Delivery costs vary significantly between sellers and geographic areas, always ask for complete delivered pricing to compare options accurately:

What Should Be Included in Your Quote:

- Container cost: Base price for the unit in specified condition

- Modification costs: All customization work clearly itemized

- Delivery cost: Transportation to your specific location

- All taxes and fees: No surprise charges at delivery

Questions to Ask Before Your Shipping Container is Delivered:

- Is delivery included in the quoted price?

- What’s your standard delivery radius?

- How much extra for deliveries beyond your standard area?

- Are there additional fees for difficult access or placement?

- What happens if weather delays require rescheduling?

Important: Some companies include delivery in their base price, others charge $200-800+ depending on distance and difficulty. Always get total delivered pricing before comparing options.

Understanding Warranties: What’s Covered & What to Avoid

Container warranties vary dramatically between sellers, and understanding what’s actually covered protects you from unpleasant surprises. Focus on structural guarantees rather than cosmetic promises.

Structural Warranty vs Cosmetic Issues

Meaningful container warranties focus on structural integrity and weather resistance, not appearance:

What Should Be Covered:

- Structural integrity: No roof collapse, wall failure, or floor weakness

- Weather tightness: Protection against water infiltration

- Door functionality: Proper door operation and sealing

- Major rust-through: Holes that compromise weather resistance

What’s Typically NOT Covered:

- Surface rust that doesn’t affect structural integrity

- Minor dents or cosmetic damage

- Normal wear from weather exposure

- Damage caused by improper use or modification

- Interior condensation in uninsulated containers

E & S Equipment Sales 2-Year No-Leak Guarantee

Our warranty focuses on what matters most, keeping your contents dry and secure:

Our 2-Year Structural Guarantee Covers:

- Zero water infiltration: Your container will remain completely dry inside

- Structural soundness: No floor weakness or wall failure

- Door operation: Doors will open, close, and lock properly

- Gasket integrity: Door seals will prevent water and pest entry

How We Stand Behind Our Guarantee:

- Free repair or replacement for covered issues

- No-hassle claim process with direct contact

Warning on Unrealistic Lifetime Guarantees

Be extremely wary of sellers offering “lifetime” or excessively long warranties, they’re often marketing gimmicks:

Red Flags in Warranty Claims:

- “Lifetime” guarantees: Often have so many exclusions they’re meaningless

- Cosmetic warranties: Promising “like new” appearance that’s impossible to maintain

- Transferable warranties: If too good to be true, probably are

- Verbal promises: Must be in writing to have any value

Questions to Ask About Any Warranty:

- Is the warranty in writing with specific terms?

- What specific problems does it actually cover?

- How long has the company been in business to honor long-term warranties?

- What’s the claims process if problems occur?

- Are there geographic limitations on warranty service?

Realistic Expectation: A 2-year structural warranty from an established dealer is far more valuable than a “lifetime” guarantee from a company that may not exist in five years.

Container Buying Red Flags

The shipping container market attracts both legitimate dealers and scammers looking to exploit uninformed buyers. Recognizing red flags protects your investment and ensures you get exactly what you pay for.

Pricing Red Flags That Signal Trouble

Unrealistic pricing is often the first warning sign of a problematic deal:

Prices Too Good to Be True:

- Below-market pricing: New containers under $3,500 or used under $1,800

- “Limited time” pressure tactics: Must buy immediately or lose the deal

- No delivery cost transparency: “Free delivery” that’s actually built into inflated pricing

- Auction-style “bidding”: Fake competition to drive up prices

Hidden Fee Warning Signs:

- Quotes that don’t include delivery costs

- Separate “documentation” or “processing” fees

- Fuel surcharges not disclosed upfront

- Last-minute “inspection” or “certification” fees

Reality Check: Quality used containers cost $2100 – $4000 delivered. New containers cost $3200 – $10,000 delivered. Anyone offering significantly less is likely hiding problems or costs.

How to Verify You’re Dealing with a Legitimate Seller

Scammers often create professional-looking websites, but their business practices reveal the truth:

Business Verification Checklist:

- Physical address: Verify with Google Street View, should show actual container yard

- Phone verification: Call during business hours, real person should answer

- Business registration: Check state business registration databases

- Better Business Bureau: Look up their BBB rating and complaint history

- Google Reviews: Read recent reviews and look for response patterns

Professional Operation Indicators:

- Knowledgeable staff who can answer technical questions

- Willingness to provide specific container photos

- Clear written contracts with terms and conditions

- Established delivery fleet or proven delivery partners

- Warranty or guarantee policies in writing

Photo and Documentation Authenticity

Fake or misleading photos are common tactics used to misrepresent container conditions:

Photo Red Flags:

- Stock photos: Generic images that don’t show your specific container

- Perfect containers at used prices: Photos too good for the asking price

- Missing container numbers: Can’t verify the specific unit you’re buying

- No interior photos: Hiding potential floor or ceiling problems

Safe Payment Practices

How you pay significantly affects your protection against fraud:

Safest Payment Methods:

- Credit cards: Best protection with chargeback rights

- Bank checks: Secure but verify delivery before payment clears

- COD delivery: Pay when container arrives as specified

Payment Methods to Avoid:

- Wire transfers: No protection once money is sent

- Cryptocurrency: Untraceable and no recourse

- Gift cards or prepaid cards: Common scammer tactics

- Cash in advance: No protection if container doesn’t arrive

*Payment Flexibility: Most reputable dealers offer flexible payment options to accommodate different customer preferences and comfort levels. At E & S Equipment Sales, we typically require a 50% deposit when your order is placed, with the remaining balance due upon delivery after you’ve had the opportunity to inspect your container. For customers who prefer to pay in full upfront, we accommodate that as well. We also offer COD (Cash on Delivery) options depending on your location and specific circumstances. The key is working with a dealer who offers transparent payment terms that match your comfort level and provides multiple secure payment options rather than demanding full payment upfront with no flexibility.

What You Need to Know About Container Markings

Every shipping container carries important identification and safety markings. Understanding the basics helps you verify what you’re buying and avoid potential issues.

Container Number: Your Container’s Unique ID

The container number appears prominently on doors and sides in this format: TCLU 123456 7

- First 4 letters: Owner/operator code

- Next 6 digits: Unique serial number

- Final digit: Check digit for verification

Why it matters: This number should match all documentation and photos your seller provides.

CSC Safety Plate: Proof of Structural Integrity

The CSC (Convention for Safe Containers) plate is the most important marking for buyers:

- Manufacturing date: Shows container age

- Maximum weights: Confirms load capacity

- Country of approval: Certification origin

- Test date: Last structural inspection

Buying Tip: A valid CSC plate indicates the container met rigorous structural standards. Always ask sellers about previous cargo use, avoid containers that transported hazardous materials or show signs of contamination.

Leasing vs Buying Cargo Containers

Not everyone needs to purchase a container outright. Leasing offers an attractive alternative that reduces upfront costs while providing the same container benefits, ultimately leading to ownership.

Container Leasing: Lower Upfront Costs with Ownership at Term End

Container leasing works like equipment financing but with a unique advantage, you own the container at the end of your term:

E & S Equipment Sales Lease Program Features:

- Term Options: 12, 24, 36 & 48 month terms available

- No Credit Check Required: Approval based on ability to pay, not credit score

- Low Entry Cost: First and last month’s rent as deposit

- Early Payoff Discount: One-time discount available for early completion

- You Own It: Container becomes yours once term is completed

When Leasing Makes More Sense Than Buying

Leasing provides advantages for specific business and personal situations:

Cash Flow Management:

- Preserve working capital for other business needs

- Predictable monthly payments for budgeting

- No large upfront capital expenditure

- Maintain credit lines for other purposes

Business Applications:

- Seasonal businesses: Avoid large upfront costs during slow periods

- Growing companies: Start with smaller payments as revenue grows

- Project-based work: Match payments to project timelines

- Tax planning: Monthly lease payments may be fully deductible

E & S Equipment Sales Lease Program Details

Our straightforward leasing process eliminates the complexity typically associated with equipment financing:

Simple Approval Process:

- Choose your container and modifications

- Select your preferred term length (12-48 months)

- Provide basic business or personal information

- Receive approval typically within 24 hours

Example Lease Scenario:

40ft High Cube Container ($7,500 purchase price)

36-month lease: Approximately $240/month

Total of payments: $8,640

Leasing Advantage: Start using your container immediately with just two monthly payments upfront, instead of $7,500 cash. Perfect for businesses needing immediate storage solutions without impacting cash flow.

What to Inspect Before You Buy a Used Container (Checklist)

Buying a used container without proper inspection is like buying a used car without looking under the hood. Even cargo-worthy containers can have issues, and knowing what to check protects your investment.

1) Check for a Solid, Leak-Free Roof

The roof bears the greatest weather stress and cargo weight. Your inspection should include:

- Visual roof walk: Look for dents, rust spots, or repair patches

- Interior ceiling inspection: Check for water stains, rust streaks, or soft spots

- Corner post examination: Ensure no separation where roof meets corner posts

- Drain hole verification: Confirm corner drain holes aren’t blocked or damaged

Red Flag: Multiple repair patches on the roof indicate a container with ongoing leak issues. Walk away from these deals, roof repairs are expensive and often temporary.

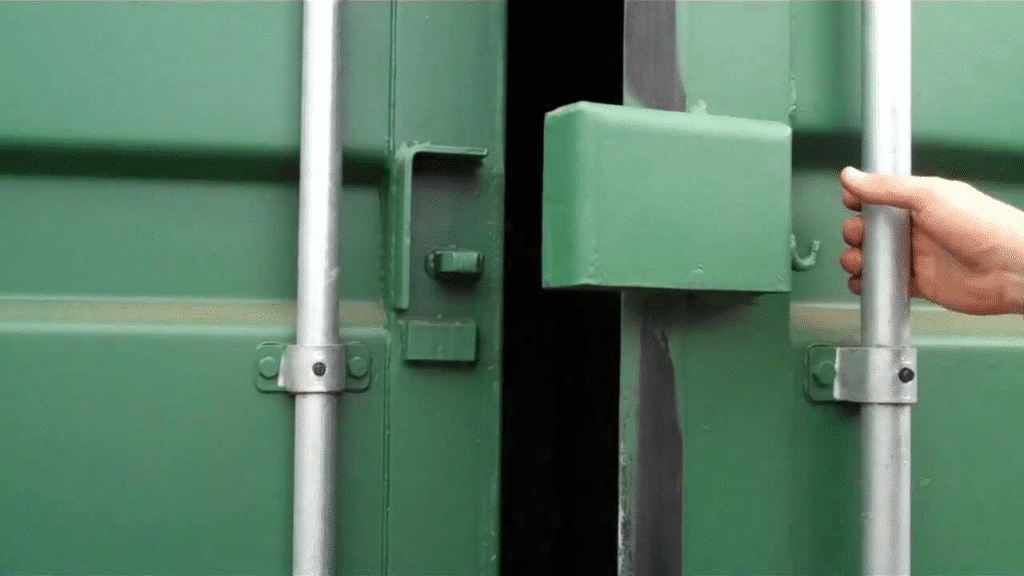

2) Doors Swing Freely and Gaskets Seal Tightly (The Light Test)

Door problems are the most common used container issue, but they’re easy to spot with proper inspection:

The Light Test Process:

- Close both container doors from the inside

- Look for light leaks around door perimeter

- Check door gasket compression and condition

- Test locking rod operation on both doors

Door Mechanism Checks:

- Doors should swing open and close without force

- Locking rods should operate smoothly without binding

- Door gaskets should be intact without gaps or tears

- Hinges should show no excessive wear or damage

3) Inspect the Floors for Strength and Integrity

Container floors endure enormous weight and stress. A compromised floor can be dangerous and expensive to repair:

Wooden Floor Inspection:

- Walk test: Step firmly across entire floor listening for soft spots or creaking

- Visual check: Look for stains, rot, or previous repair patches

- Smell test: Strong odors may indicate contamination or chemical exposure

- Moisture check: Feel for dampness that could indicate ongoing leaks

Steel Floor Inspection (if applicable):

- Check for rust-through spots or thin areas

- Look for previous welding repairs

- Ensure no sharp edges that could cause injury

- Verify proper drainage slope toward door end

4) Professional Quality Inspection Standards

Reputable dealers provide comprehensive quality inspection with every used container purchase. Look for sellers who offer:

- Structural integrity verification by experienced inspectors

- Weather-tight testing with documentation

- Photographic documentation of your specific container before delivery

- Written quality guarantees covering structural and weather-sealing issues

Popular Modifications & Customizations

A standard shipping container is just the beginning. Shipping containers modifications transform basic storage into functional workshops, retail spaces, or specialized storage solutions that perfectly match your needs. E & S Equipment Sales offers comprehensive modification services to create your ideal container solution.

Access and Security Upgrades

- Roll-up doors: Easy one-handed operation, weather-tight seal, lockable security

- Man doors (personnel doors): Quick access without opening large cargo doors

- Lock boxes: Secure, weather-resistant storage for keys and small valuables

Climate and Ventilation Solutions

- Wall AC units: Cost-effective cooling for moderate climate control

- Mini split HVAC: Efficient heating and cooling with precise temperature control

- Heat: Electric or propane heating systems for cold climates

- Louvered vents: Passive ventilation to prevent condensation

- Roof turbines: Wind-powered exhaust ventilation

Power and Electrical Systems

- Interior lights: LED fixtures for energy-efficient illumination

- Outlets: Standard and specialty electrical outlets throughout the container

- Breaker panel: Professional electrical distribution and safety systems

- Exterior power inlet: Easy connection to external power sources.

Interior Improvements and Functionality

- Insulation or spray foam: Temperature control and condensation prevention

- Framing: Interior wall framework for mounting and finishing

- Finished walls and ceiling: Professional interior appearance

- Shelving: Custom storage solutions for organization

- Workbenches: Built-in work surfaces for workshops

- Partitions: Divide space for multiple uses or security

Flooring Upgrades

- Marine plywood upgrade: Smooth, durable surface over standard wooden floors

- Vinyl or epoxy floor: Easy-clean, professional-grade flooring

- Floor drains: Washdown capability for maintenance and cleaning

- Thresholds: Weather sealing and trip hazard elimination

Openings and Service Features

- Side cutouts: Custom openings for equipment or vehicle access

- Serving windows: Customer service openings for retail applications

- Pass throughs: Material transfer openings between spaces

Exterior and Branding Options

- Custom paint: Any color to match your preferences or requirements

- Color match: Blend with existing buildings or landscape

- Logos and numbering: Professional branding and identification

Site Use Accessories

- Container ramps: Easy equipment and vehicle access

- Steps: Safe access to elevated door openings

- Small awnings: Weather protection for door areas

Preparing for Delivery

Proper site preparation prevents delivery delays, additional costs, and potential damage to your property. Most delivery problems stem from inadequate preparation that could have been easily avoided.

Site Preparation: Is Your Location Level and Clear?

Container delivery requires specific site conditions for safe placement:

Ground Preparation Requirements:

- Level surface: No more than 3-inch slope across container length

- Firm foundation: Compacted earth, gravel, or concrete pad

- Adequate drainage: Prevent water pooling around container

- Clear access path: Remove debris, landscaping, or obstacles

Overhead Clearance:

- Minimum 15 feet clearance for delivery truck operation

- Check for power lines, tree branches, or building overhangs

- Consider container height plus delivery equipment reach

Understanding Delivery Truck Space Requirements

Delivery trucks need substantial maneuvering space that surprises many first-time buyers:

Tilt-Bed Truck Requirements (Most Common):

- Truck length: 60-70 feet including container

- Width clearance: 10 feet minimum for safe operation

- Turning radius: 50-foot circle for positioning

- Ground pressure: Firm surface to prevent truck from sinking

Crane Delivery (For Tight Spaces):

- Crane setup space: 30-foot square area adjacent to placement site

- Boom clearance: No obstacles within crane’s swing radius

- Additional cost: $200-400 surcharge for crane delivery

Choosing a Foundation: Gravel Pads, Concrete Blocks, or Railroad Ties

Your foundation choice affects container longevity, accessibility, and maintenance requirements:

Gravel Pad Foundation (Most Popular):

- Cost-effective: $200-400 for typical installation

- Excellent drainage: Prevents water accumulation

- Level adjustment: Easy to modify if settling occurs

- Specifications: 4-6 inches of compacted gravel, 2 feet wider than container

Concrete Block Foundation:

- Permanent solution: Stable and long-lasting

- Height adjustment: Raises container above ground moisture

- Access friendly: Allows airflow underneath container

- Requirements: 6 blocks minimum (one at each corner plus mid-points)

Railroad Tie Foundation:

- Traditional method: Proven over decades of use

- Load distribution: Spreads weight across entire container length

- Adjustment capability: Shim for perfect leveling

- Considerations: Treated lumber may have environmental concerns

What to Expect on Delivery Day

Understanding the delivery process helps you prepare and ensures everything goes smoothly:

Pre-Delivery (Day Before):

- Driver calls to confirm appointment and review access

- Final site preparation check

- Arrange for someone to be present during delivery

- Clear vehicles and obstacles from delivery area

During Delivery:

- Truck arrival: Driver surveys site and confirms placement location

- Container positioning: Careful placement using hydraulic systems

- Final positioning: Adjust location within reasonable limits

- Inspection and acceptance: Walk-through with driver before departure

Important: Once the container is placed, moving it requires another delivery charge. Confirm the exact position before the driver leaves to avoid additional costs.

Frequently Asked Questions About Buying Shipping Containers

How much does a shipping container cost?

New Storage Container Pricing:

20ft Standard: $3200 – $3900

40ft High Cube: $4500 – $5900

Used Storage Container Pricing:

20ft Standard Height Cargo Worthy : $2100 – $3000

40ft Standard Height Cargo Worthy : $2600 – $3200

40ft High Cube Cargo Worthy : $2700 – $3600

Prices typically include delivery and sales tax unless tax exemption documents are provided.

Can I lease a shipping container instead of buying?

Yes! Storage container leasing offers lower upfront costs with ownership at term end. E & S Equipment Sales offers 12, 24, 36 & 48 month terms with no credit check required. You pay first and last month’s rent as deposit, make monthly payments, and own the container when the term completes. Early payoff discounts are available. This option helps preserve cash flow while providing the same storage container benefits.

What are the most common mistakes to avoid when buying a container?

The five most expensive mistakes we see buyers make:

Choosing the wrong size: Measure your space and needs carefully, moving costs add up quickly

Inadequate site preparation: Poor foundations cause delivery problems and long-term issues

Buying sight unseen: Always inspect used containers or demand detailed photos

Ignoring permit requirements: Check local regulations before delivery to avoid violations

Focusing only on price: Cheap containers often have expensive hidden problems

How can I avoid container buying scams?

Key red flags include prices significantly below market ($1,800 for used containers), sellers who won’t provide specific container photos, payment requests via wire transfer or gift cards, and no physical business address. Always verify the seller’s physical location, check their Better Business Bureau rating, demand photos of your specific container with visible container numbers, and use secure payment methods. Never pay the full amount until you’ve inspected the container on your property.

Do I need a permit for a shipping container on my property?

Generally NO permit required for:

Temporary storage (under 180 days) in many jurisdictions

Agricultural use on properly zoned land

Industrial sites with appropriate zoning

Permit likely required for:

Permanent residential storage structures

Any modifications involving plumbing or electrical

Commercial use in retail or office applications

Placement in HOA-governed communities

Always check with your local building department before ordering. We provide permit guidance based on your specific location and intended use.

How long will a used shipping container last?

Container lifespan depends on condition, climate, and maintenance:

Cargo-Worthy Containers: 15-20 years of reliable service with minimal maintenance

Wind & Watertight Containers: 10-15 years depending on initial condition

Factors that extend life:

Proper foundation preventing ground contact

Regular painting every 5-7 years

Dry climate with minimal salt air exposure

Appropriate ventilation preventing condensation

Factors that reduce life:

Direct ground contact causing rust

Coastal environments with salt air

Poor drainage causing standing water

Neglected maintenance and repairs

Ready to Find Your Perfect Container?

You now have the complete knowledge needed to make an informed container buying decision. This shipping container guide covered everything from sizing and conditions to modifications and delivery, ensuring you avoid costly mistakes and get exactly what you need.

Your container purchasing process next steps:

- Define your requirements: Size, condition, timeline, and budget parameters

- Verify your site: Ensure proper access and foundation preparation

- Check local regulations: Confirm permit requirements for your area

- Request your quote: Get specific pricing and availability from reputable dealers

At E & S Equipment Sales INC., we’re ready to guide you through every step of how to buy shipping containers and storage containers successfully. Our commitment to transparent pricing, quality containers, and professional service has helped over 1,000 customers find their perfect storage container solutions using this proven container buying guide approach.

Recent Comments